Atomic force microscopy (AFM) is a cutting-edge scanning probe microscopy technique which enables the visualization of surfaces with atomic or nanometer-scale resolution. Its operational principle lies in measuring the force interactions between a minuscule probe tip and the sample surface.

The goal of this article is to highlight AFM image processing methods and analysis techniques including particle analysis (grain analysis), roughness analysis and force curve analysis and examine their fields of application.

What is an AFM image?

AFM images serve as graphical representations of physical parameters captured on a surface. Essentially, they comprise a matrix of data points, each representing the measured value of an associated physical parameter. When multiple physical parameters are simultaneously measured, the resulting images are termed “multi-channel images” and contain one image layer per physical property measured.

The versatility of AFM images

AFM images capture a diverse range of surfaces, encompassing materials, biomolecules and supramolecular structures. They also reveal physical properties of the surface, such as surface roughness, critical dimensions, stiffness and defect density.

AFM image of SARS-CoV-2 virion (3D view generated with MountainsSPIP® software)

Processing AFM images: a crucial step for optimal results

AFM image processing has significant impact on image quality. While it is important to carefully consider sample preparation and probe selection, post-acquisition measures can be equally efficient allies in improving image quality. These include:

- Leveling or flattening to correct unevenness caused by the scanning process. This is crucial for accurate measurements of surface features like roughness or particles. Plane fitting algorithms are used to rectify such disparities.

- Lateral calibration to correct image distortions like linearity or scaling. Reference surfaces, acquired under identical conditions to those of the sample image, serve as calibration tools.

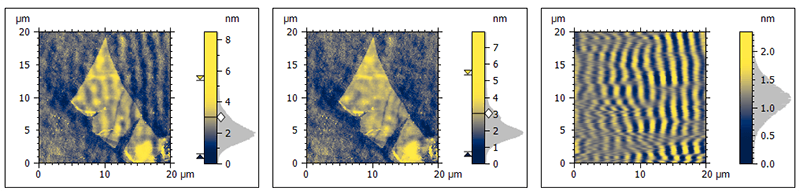

- Noise filtering: this step eliminates unwanted noise from the image through the application of spatial filters, Fourier transforms and other techniques. Low-pass filters are used to remove high-frequency noise, while median filters replace each pixel with the median value of surrounding pixels, eliminating noise unrelated to the underlying signal.

Noise filtering is a critical step of AFM image analysis: source image (left), filtered image (middle) and noise removed (right).

Extracting quantitative insights from AFM images

AFM image analysis entails extracting quantitative and qualitative information from surfaces. The primary AFM image analysis techniques encompass:

- Topographic analysis: measurement of surface roughness, step height and other physical parameters.

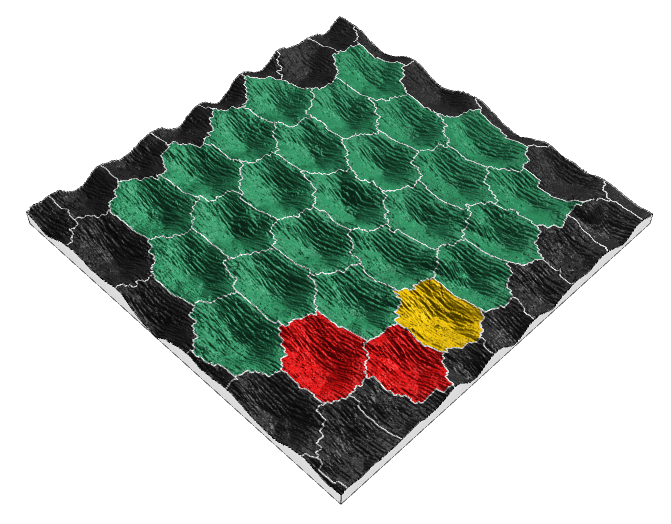

- Particle analysis: quantification of the size, shape, and distribution of particles or grains present on the surface.

- Nanomechanical properties: assessment of the mechanical properties of surfaces and materials, including stiffness, elasticity and adhesion. This technique provides valuable insights into material properties at the nanoscale.

Particle analysis involves detection and characterization of structures in AFM images.

Beyond the core techniques: the wider spectrum of AFM image analysis

Besides the aforementioned core AFM image analysis techniques, additional methods allow users to extract valuable information from AFM images.

Phase analysis measures the surface potential, while spectroscopy quantifies the chemical composition of a surface. Force curve analysis (or force spectroscopy analysis), magnetic force microscopy (MFM) and many other types of analysis can also give valuable information about the sample.

AFM image analysis: a versatile tool for a broad scope of applications

AFM image analysis has applications in numerous fields, including materials science, biology, chemistry, and nanotechnology. Here are a few notable examples:

- Characterization of material surfaces: AFM unveils the roughness, crystallinity, and composition of material surfaces, aiding understanding of their physical and chemical properties.

- Investigating biomolecules: AFM provides visual insights into the structure and dynamics of biomolecules like proteins and nucleic acids, facilitating the comprehension of biological mechanisms.

- Assessing nanoparticles: AFM characterizes the size, shape, and distribution of nanoparticles, essential for various applications.

- Critical dimension analysis in semiconductors: AFM measures the size and shape of semiconductor structures, allowing analysis of their nanoscale behavior.

![]()

AFM image analysis software is a precious ally when analyzing critical dimensions in semiconductors.

The choice of AFM image analysis technique depends on the specific application. A powerful analysis software suite such as MountainsSPIP® software emerges as a strong ally for any user analyzing AFM data and offers a comprehensive set of features adapted to each analysis technique.

In conclusion, AFM image analysis stands as a powerful tool for garnering quantitative and qualitative information about surfaces at the atomic or nanometer scale. Its versatility, spanning various fields, makes it an invaluable tool for research and development.

Author : Mathieu Cognard, product manager for SPM applications, Digital Surf