Surface texture has always been a difficult discipline to master, due to complex filtration conditions, numerous parameters and complicated notations. This complexity is probably why users often only retain the Ra parameter (and forget about filtration). To add to this, the new areal standard ISO 25178 adopts a different system from the profile standard.

ISO expert François Blateyron looks at the big picture and how this could be simplified in the future.

Why three variants for profile parameters?

Profilometry was born in the 1940s, pushed by the urge to improve the quality and efficiency of mechanical components used in weapons, planes, vehicles and ships during World War II. The foundations of the discipline were forged by mechanical engineers for mechanical engineers. After the war, it was further developed to accompany the growth of the automotive industry and later other industries such as medical implants, appliances and electronic devices.

The nature of surface texture is based on the lateral wavelength of irregularities. Geometrical form and form errors are excluded from surface texture, leaving three components: primary profile, roughness profile and waviness profile, each separated by filters. Roughness is by far the most common surface characteristic, having an important impact on surface functions such as wear or friction. Waviness is key for sealing and sliding functions.

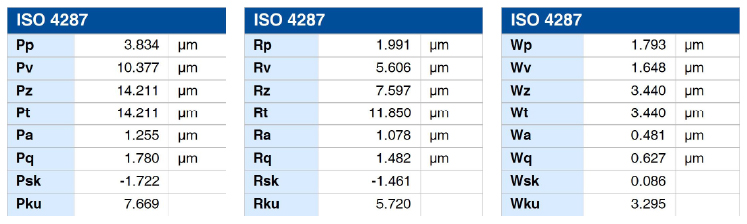

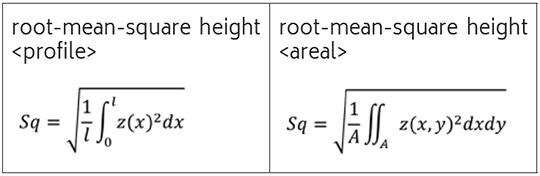

Surface texture specifications are expressed via parameters that imply filtration conditions in their name. For example, the “quadratic mean height” parameter corresponds to Rq on the roughness profile, Wq on the waviness profile and Pq on the primary profile. The definition of these three parameters is the same, but the profile on which they may be applied is filtered differently. Thirteen parameters defined in ISO 4287:1996 suddenly become thirty-nine!

But that’s not all. Some of these parameters are calculated by small segments called sampling lengths and averaged, and some are calculated over the evaluation length. (It is interesting to note that this complex method was however not used in the American ASME B46.1 standard which is much more practical than the ISO standard although perhaps less rigorous. See our Surface Metrology Guide for more details.

![]()

There are historical reasons for this complexity, one of them being that, in the 1980s, the dispersion of results between profilometers of different kinds required stabilization by an averaging process.

Why only one variant for areal parameters?

Areal surface texture started in the 1990s by simply extrapolating profile parameters to the third dimension. Then, the European project Surfstand drafted the future standard and justified the benefit of areal analysis by better stability and better functional correlations. After a period where areal parameters were called sRa, sWa and sPa, it was finally decided that a single symbol (Sa) should be used regardless of filtration conditions. For more details see here.

One of the main reasons for this was that, on a rectangular surface, it may be possible to have a roughness-like surface in one direction and a waviness-like surface in the perpendicular direction. Also, new analysis methods such as multi-scale exploration of the surface or morphological filters generate different kinds of filtered surfaces that are neither roughness nor waviness.

ISO 25178 was developed with the idea that “Nature is tridimensional” and new concepts have been introduced to prepare a standard of the new millennium. Improved mathematical foundations and simpler concepts have been used, with the intention to these should also apply to existing profile standards when they become due for revision.

Why not simplify in the future?

The revision of profile standards has now started with the draft of ISO 21920 parts 1-3. Why not use this as an opportunity to modernize our standard portfolio? Why not replicate the general concepts introduced in the areal standard and get rid of the most complex parts of our old standards? The debate is open at ISO but old habits die hard in some industries.

For sure, today’s surfaces are much more complex than in the past. They are often structured or stratified to program a specific function. Hydrophobic surfaces use micropillars, nanoprinting of periodic structures allow the surface to be colored without ink or paint, laser textured surfaces optimize friction and save energy, etc.

These surfaces require modern analysis tools, such as watershed segmentation, biorthogonal wavelets, bandpass filtering, multi-scale geometric analysis, autocorrelation function, etc. Profiles and surfaces can be filtered with many different filters (see ISO 16610 series), each having specific strengths for specific applications. The roughness/waviness duality is no longer valid for complex surfaces although it remains useful on isotropic surfaces obtained by traditional manufacturing processes.

Above: Profile/areal parameters revision is a hot topic currently discussed by ISO technical committee 213/working group 16

So, how can we extend our standards to embrace these new applications?

Let’s imagine defining a single notation for surface texture parameters, regardless of how the surface is measured and how measured data is modified and filtered. Let’s call these parameters Sx with S to symbolize surface and a subscript x to define the type of parameter. For example:

And one could also imagine similar definitions on roundness profiles, cylinders, freeform surfaces, parametric profiles, etc. This would avoid multiplying parameter names as we apply them to different data types.

Of course, form association (leveling, form fitting) and filtration conditions (bandwidth or scale limitation) should be given explicitly with the specification or in a condition box referenced on the specification symbol. But this would be clearer than relying on defaults that the majority of users barely understand.

Existing drawings using old parameters and notations could still be used. They refer to former standards. But why not use simpler, clearer and more flexible notations for new standards crafted for modern surfaces produced by new manufacturing processes and by those yet to come?

Your view is important!

Simplification is one of the hot topics currently undergoing discussion at ISO TC213/WG16. Users are invited to contribute to this discussion, and not only those from the mechanical or automotive industries (ISO standards are now used much more widely than these).

As an active member of this working group, I would like to hear feedback from users in many different fields of application who use profile and/or areal parameters and who struggle with the complexity. I would like to hear from teachers, metrologists, engineers and researchers.

Please do not hesitate to send us your thoughts and ideas, via email or our social network pages:

Author : François Blateyron

Resources :

https://guide.digitalsurf.com/en/guide-profile-parameters.html