Many users consider that roughness is (only) represented by Ra (on a profile) and Sa (on a surface). While these are among the most commonly used parameters, they are often the least meaningful when it comes to fully understanding surface texture. Among the wide range of available parameters, those based on material ratio, that is represented by the Abbott curve, are certainly amongst the most valuable for understanding surface characteristics.

François Blateyron, Digital Surf’s senior surface metrology expert, explains the benefits of these parameters and why users should move beyond Ra or Sa for evaluating the functional behavior of mechanical components.

Height distribution

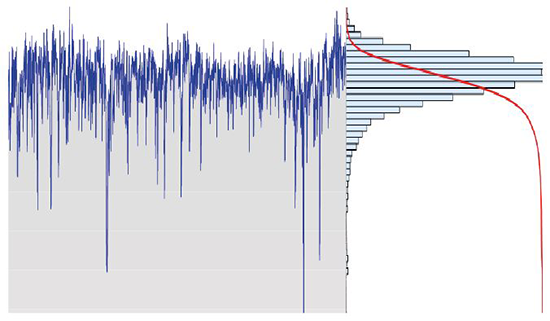

Profile or surface heights can be represented as a statistical distribution showing the percentage of data points that fall within each height range (bin). This distribution is essentially a histogram of heights, and provides a fundamental view of surface topography.

Abbott curve

The Abbott curve is built by summing the height distribution values, from the highest to the lowest value, corresponding to 0% to 100% on the Abbott curve. It provides the material ratio value in % for a given depth taken from a reference that is by default the highest point.

Above. A profile (left) and its height distribution (right) in blue with Abbott curve in red.

Beyond roughness height

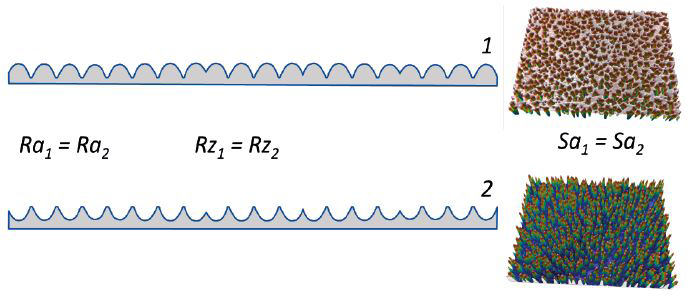

The following illustration shows two profiles with identical Ra and Rz values but clearly different functional behavior. Imagine if you had to walk barefoot on one of them, you would probably prefer the first one! This highlights how height-based parameters alone cannot distinguish between functionally different surfaces.

Material ratio parameters

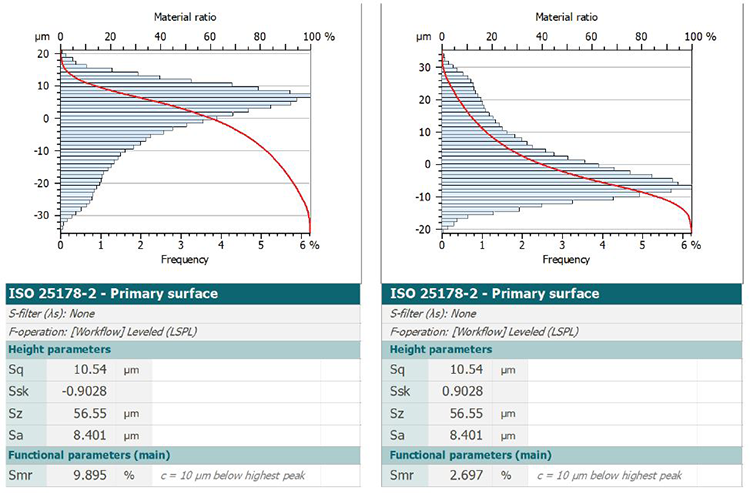

The following two height distributions clearly show how the texture is distributed between plateaus and deep valleys.

Traditional height parameters (Sq, Sa, Sz) cannot distinguish between such surfaces. However, material ratio-based parameters such as Ssk (skewness) and Smr (material ratio) can.

- Ssk is negative when the surface has plateaus (flat upper surface) with a few valleys, pores or scratches, and positive when it has flat bulk regions with particles or ridges above.

- Smr represents the material ratio at a given depth and can be used to query particular values of the Abbott curve and set tolerances.

Additional useful parameters include:

- Sku (kurtosis) which indicates if the distribution is narrow or wide.

- Smc, the inverse material ratio that gives the height for a given material ratio.

- Sdc, the height difference between two material ratios.

All of these also have equivalents on profiles: Rsk, Rku, Rmr, Rmc, Rdc.

Lubrication and wear

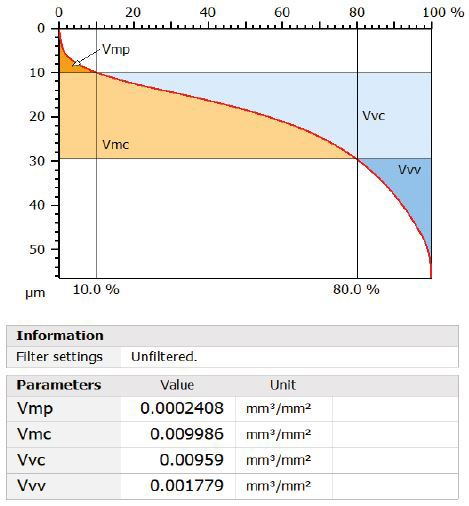

Material ratio-based parameters, especially volume parameters, are highly effective for assessing mechanical functions like lubrication and wear.

Calculated from segments of the Abbott curve, they allow quantification of material and void volumes:

- Vmp is the material volume of peaks, that are most prone to wear during contact.

- Vmc is the material volume of the core, which corresponds to the main contact section.

- Vvv is the void volume of the valleys, that characterizes the volume of lubricant retained in the lowest parts of the texture.

- Vvc is the void volume of the core.

These parameters are available for profiles in ISO 21920-2, with Rvmp, Rvmc, Rvvc and Rvvv.

Automotive parameters

The Rk family of parameters has long been used in the automotive industry for characterizing profiles.

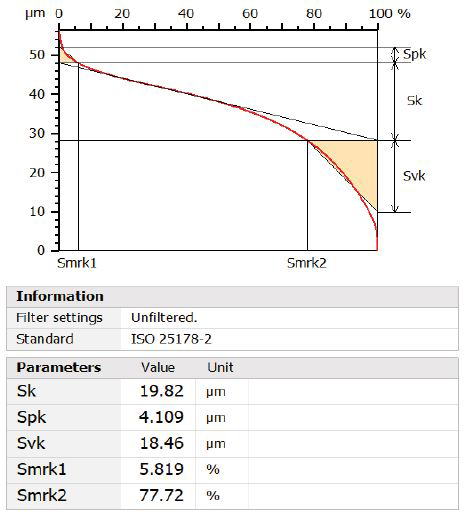

These parameters are calculated by graphical construction on the Abbott curve. They include:

- Sk (core height)

- Spk (reduced peak height)

- Svk (reduced valley height).

- Smrk1, Smrk2 (material ratios of the separations between domains).

Originally developed for profiles (in ISO 13565-2, now included in ISO 21920-2) with Rk, Rpk, Rvk, Rmrk1 and Rmrk2, these parameters have helped optimize engine efficiency for over 30 years and are now being adopted in other industries.

Final thoughts

There is far more information to extract from a texture than just its height. Parameters based on material ratio, sometimes calculated with an appropriate filter, provide valuable control of the workpiece function.

If you’re interested in learning more about material ratio-based parameters, and areal analysis in general, make sure to view our webinar which provides practical demonstrations and tips for achieving the best results.

You can also download a Free Trial of MountainsMap® analysis software and start calculating material ratio-based parameters on your surface data today.

Resources :

For more on material ratio and other surface parameters, visit our Surface Metrology Guide.