Pharmaceutical tablets are the solid dosage forms of a medicine. They are made from a variety of active substances which are then pressed and molded into a solid form. They are among the most used form of oral drugs in the market due to their easy administration, low manufacturing cost and high physical and chemical stability.

This type of drug is usually enveloped in a coating which serves a multitude of purposes. It allows to mask the taste and odor of the tablet, it protects the tablet’s chemical and physical makeup and, most importantly, allows for the controlled release of the substances into the system.

Such coatings should be strong and stable enough to survive the handling of the tablets as well as to extend the life of their different components.

Profilometry analysis for roughness measurement

The profilometer manufacturer NANOVEA conducted a study of different pharmaceutical tablets -coated and uncoated – in order to study their surface roughness with the use of a profilometer.

A profiler is a measuring instrument that scans the topography of a sample in order to quantify surface characteristics and to measure surface finish. It allows for the detection of very small surface variations which makes it ideal for quality control tests.

Topography Analysis

For this study, researchers used a NANOVEA HS2000 Profiler to measure the average surface roughness of three different tablet surfaces. The data obtained was then analyzed with NANOVEA’s Professional 3D software based on Mountains® software.

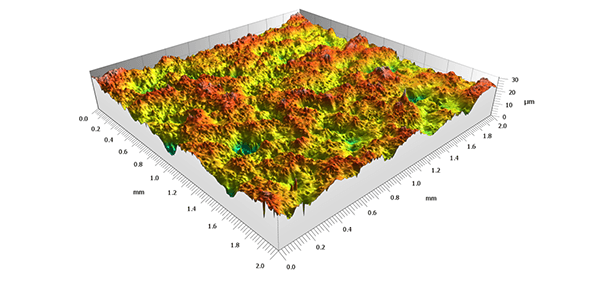

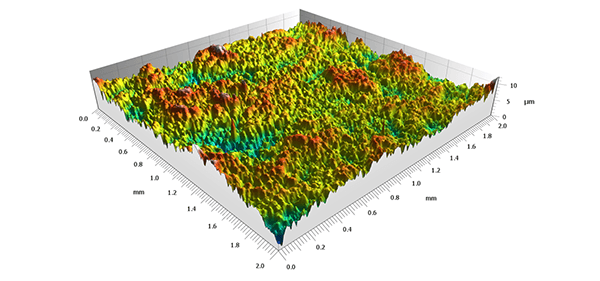

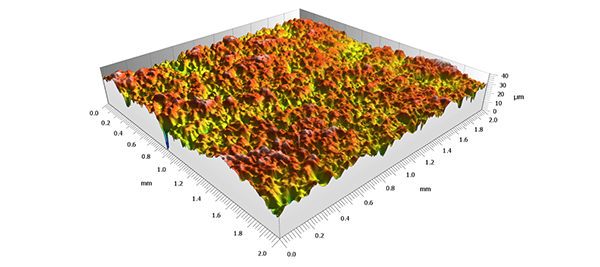

2D and 3D height maps of each tablet’s surface topography were generated allowing quick visual identification of surface features such as pits or peaks.

Above: a 3D view of the surface of one of the Tylenol samples.

Above: a 3D view of the surface of one of the Advil samples.

Above: a 3D view of the surface of one of the Excedrin samples

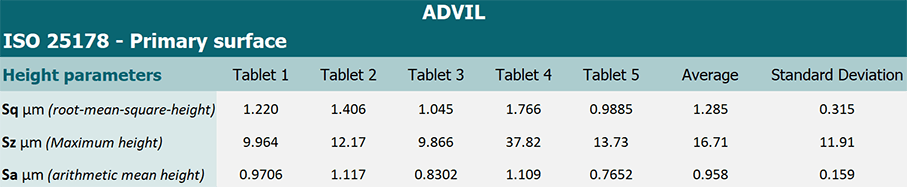

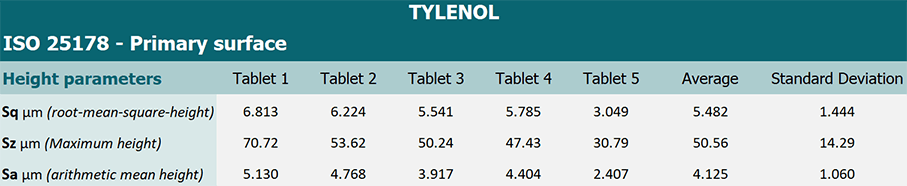

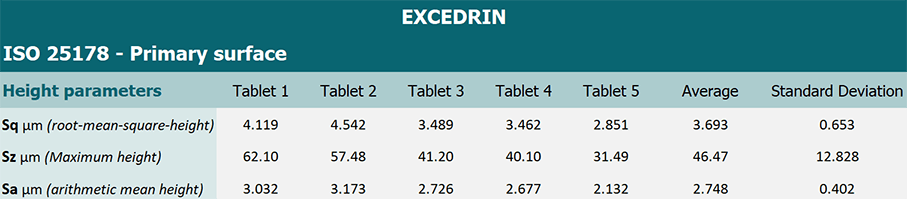

Furthermore, the arithmetic height, root-mean-square height and maximum height of five tablets from each batch was calculated with Mountains®.

The calculated values confirmed researchers’ assumptions that tablets that have a protective coating also have lower surface roughness. This type of analysis can be very useful for manufacturers in quality control tests of drugs, including analysis of large batches due to low scan-time and software automation features.

References

This case study was originally published by NANOVEA and written by Jocelyn Esparza.

Read more

Mountains® tools used

- The pseudo-color 2D and 3D views: The 2D and 3D view studies were used for high quality visualization of the surfaces’ topography.

- The parameters table: The parameters table study was implemented to visualize ISO 25178 height parameters of the analyzed surfaces.

Instruments & software used

NANOVEA HS2000 with High-Speed Line Sensor + Professional 3D software based on Mountains®.