It is well known that the current COVID-19 pandemic represents a serious problem for global health systems. Because of this, the control of surface-transmitted infections is highly desirable. A group of researchers from the University of Ferrara, Italy, defined a general procedure to characterize new materials obtained by anodic oxidation1. These types of surfaces, due to their nano-porous structure, act as reservoirs of silver ions which in turn confer antimicrobial properties to the surfaces. Anna Nastruzzi, one of the researchers involved in the study, explains more.

“We recently investigated different approaches for surface modification with the aim of reducing contamination, including the use of biological active metals” explains Anna Nastruzzi, Materials Science Engineer.

“This approach appears particularly interesting because the obtained material has an appropriate balance between the antimicrobial and mechanical properties, both of which are suitable for engineering applications.

In order to explore the potential of anodized aluminium alloys, our team investigated the tribological, anticorrosive and antimicrobial performances of a new material obtained by an innovative anodic oxidation, defined as Golden Hard Anodizing GHA.®” she says.

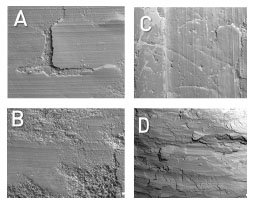

Figure 1. Representative SEM images relative to the pin-on-disk wear tests on GHA specimens. The images are relative to analyses showing different mechanisms of wearing such as: delamination (A), three body (B), abrasive (C) and tribo-oxidative (D).

Analysis of anodic oxide and GHA materials

The laboratory of the Metallurgic Group within the Department of Engineering and the Laboratory of Biomaterials and Encapsultion (BEL) within the Department of Chemical, Pharmaceutical and Agricultural Sciences, both at the University of Ferrara, performed a series of tribological determinations through 3D wear trace reconstruction (profilometric analysis). In addition, the morphology of the wear surfaces was studied by means of a scanning electron microscope (SEM) and EDS analyses.

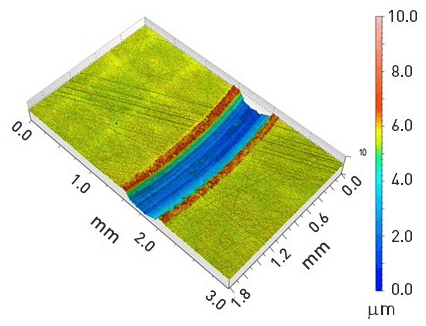

“The different analyses that were carried out by our team were performed using a non-contact profilometer and processed with MountainsMap® software. We employed the following operators in our workflow: spatial filter, fill in non-measured points, form removal, 3D surface reconstruction of the analyzed area and extracted profile.

By using a non-contact profilometer, we were able to investigate the surface topography before the tribological tests and, at the end of the tribological tests, to scan and acquire each wear track”.

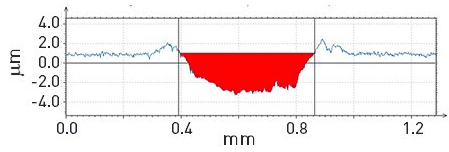

The surface topography was expressed by the parameters Rz, Ra, Rq, Rsk and Rku. “Rsk is particularly important as it gives information on the morphology of the surface texture” Nastruzzi explains. “Positive values correspond to high peaks spread on a regular surface (distribution skewed towards the bottom) while negative values are found on surfaces with pores and scratches”.

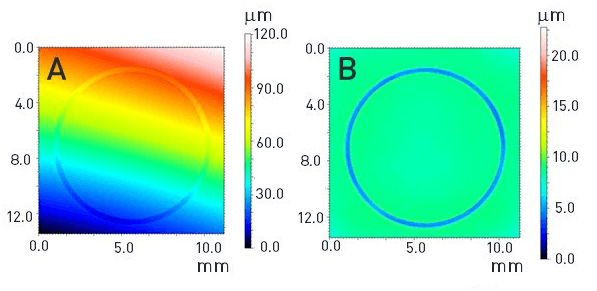

Figure 2. Three-dimensional wear trace reconstruction process performed by Mountains® software to calculate the area of the wear trace after pin-on-disk tests. (A) Raw Pseudo-colour image, (B) image after filtering (Filter Median Denoising 3×3) and form removal (Form removed: polynomial of order 4).

“With the help of Mountains® software, we were also able to calculate the wear volume, starting from the (2D) pseudo-colour view (see figure 2A, above) and by applying the filtering and form removal operators (see figure 2B, above). Finally, the volume was computed by multiplying the cross-sectional area by the wear distance”.

Conclusion

“We found GHA to be a material with intrinsic antimicrobial properties and elevated mechanical, tribological and anti-corrosive features. Its treatment with silver ions is of significant importance in reducing the risk of contamination and preventing epidemic outbreaks.

In this study, MountainsMap® software was successfully used to characterize the GHA in view of its final application. Notably, it allowed for the determination of the initial roughness and of the wear rate by calculating the wear track area”.

Figure 3. 3D view of the wear track.

Figure 4. Extracted profile and cross sectional area evaluation.

1 An electrochemical method for the production of an oxide film on a metallic substrate.

About the authors

Anna Nastruzzi (Laboratory for Nuclear Materials), Franco Cicerchia (G.H.A. Europe s.r.l), Annalisa Fortini (Department of Engineering, University of Ferrara) and Claudio Nastruzzi (Department of Chemical, Pharmaceutical and Agricultural Sciences, University of Ferrara).

Read more

Gold hard anodized (GHA) materials with antimicrobial surface properties: mechanical, tribological, and microbiological characterization. Nastruzzi, A., Cicerchia, F., Fortini, A. et al. doi.org/10.1007/s42247-021-00180-y

Instruments and software used

Non-contact 3D optical profilometer, scanning electron microscope + MountainsMap® software.