In the semiconductor industry, precise characterization of nanostructures is essential to ensure device performance and reliability. Among the key parameters, Line Edge Roughness (LER) and Line Width Roughness (LWR) play a critical role in process control.

Scanning Electron Microscopy (SEM) is widely used for inspecting these variations, but effectively leveraging SEM images requires advanced analysis tools. Mountains® software provides a dedicated solution for accurate, automated and robust LER measurements, ensuring reliable results regardless of imaging conditions such as accelerating voltage.

Feature overview

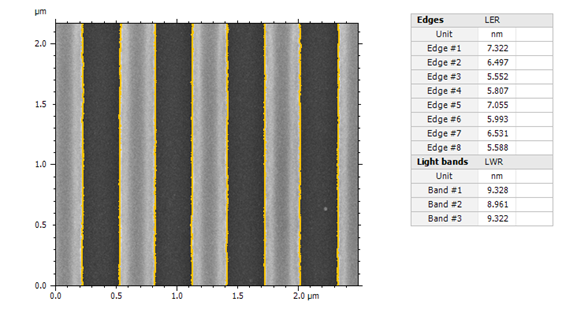

The LER analysis tool in Mountains® automatically detects structure edges and extracts analysis bands to compute Line Edge Roughness (LER) and Line Width Roughness (LWR) to deliver precise insights into edge and width variations.

1. Edge detection and LER computations

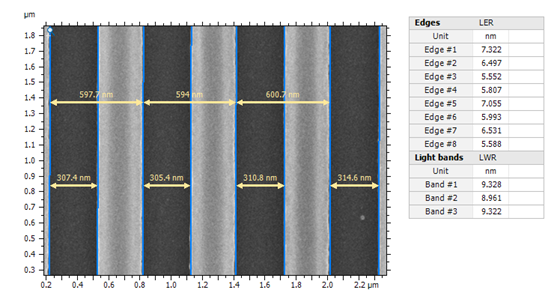

In addition to roughness parameters, the tool also measures critical horizontal dimensions, such as trench width and pitch.

2. Horizontal Critical Dimensions characterization

Advanced detection algorithms ensure robust profile extraction, maintaining accuracy even under varying SEM acquisition conditions.

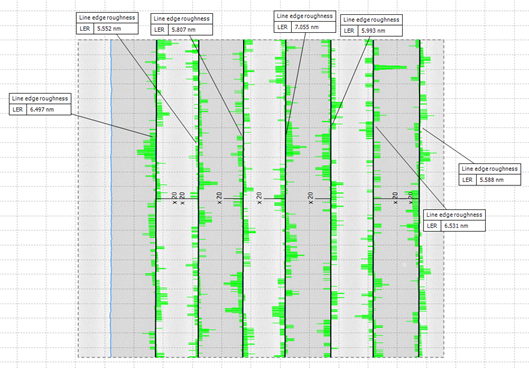

Edge extraction and deviation mapping

In addition to calculating roughness parameters, the tool allows for precise edge extraction, enabling a detailed analysis of pattern deviations. By isolating the contour of structures, users can visualize edge variations with a very high level of accuracy.

3. Deviation mapping. To facilitate interpretation, differences compared to the ideal edge are deliberately amplified for better visibility.

This enhanced display makes it easier to detect irregularities that could impact semiconductor fabrication. When combined with quantitative roughness measurements, this visualization provides a comprehensive assessment of line integrity and process stability.

Real-time processing and batch processing

One of the key strengths of the Mountains® LER tool is its real-time processing capability, allowing instant update of results when parameters are adjusted or new data loaded. Automating the process in this way ensures repeatability and minimizes manual intervention errors as well as potential operator subjectivity.

Mountains® provides powerful statistical tools to study the distribution of LER, LWR and critical dimension measurements. This enables a comprehensive evaluation of process stability and variability, as well as detection of outliers.

Instrument & software used

Scanning Electron Microscope & MountainsSEM® software